How Can Blockchain Revolutionize the Manufacturing Industry?

Blockchain technology has already shown the potential to change almost every industry in the world. In fact, it is bringing revolutionary changes in FinTech, healthcare, entertainment, logistics, manufacturing, and other industries. Above all, Blockchain in manufacturing is expected to have a market value of $566.2 million by 2025.

Moreover, Blockchain is regarded as the safest technology for tracing data and handling complex records of transactions. This technology also guarantees better transparency in the production process and delivery of the finished products. Above all, it is believed that Blockchain will significantly change the traditional supply lines and quality control processes and improve regulatory standards. In this blog, we are going to discuss the role of Blockchain in manufacturing industry.

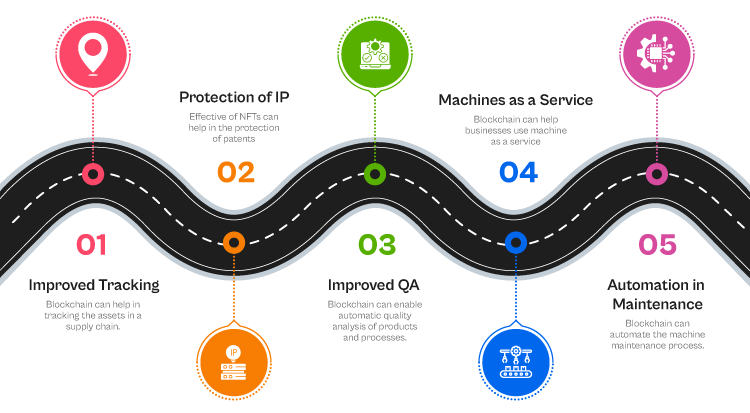

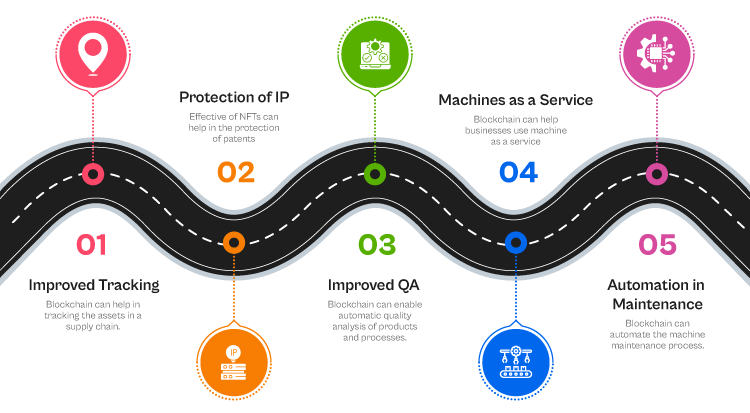

Implementing the technology in manufacturing can result in the following impact;

- Improved monitoring of the supply chain with better transparency

- Better means to detect and fight counterfeit

- Support in designing high-complexity products

- Improvement in identity management

- Accurate tracking of assets

- Improvement in quality assurance

- Regulatory compliance

Before we understand the detailed impact of Blockchain, let’s discuss the technology first.

What is Blockchain?

Blockchain is a decentralized ledger technology used for keeping track of transactions present on multiple nodes of a network. Since the data is present on multiple computers, so it is present on an immutable ledger.

Blockchain technology is known for providing the best solution for the instant delivery of information on an immutable ledger with better transparency and security. Only permissioned members on the network can access this data. Instead of using a centralized server, Blockchain technology heavily relies on decentralization. Therefore, it has become an amazing solution for tracking accounts, payments, transactions, orders, production, etc.

For this reason, many prominent businesses consider investing in Blockchain development to innovate their processes and workflow. Therefore, Blockchain in manufacturing industry could be an ideal solution for many challenges as well.

Why is Blockchain So Popular?

Since it is the latest technology, many industries prefer to invest in Blockchain development. It would open up a lot of possibilities for different industries from diverse industries. These are some remarkable benefits of Blockchain technology;

1. Security

Blockchain is known for providing users and businesses with superior security. Above all, this is only possible with the help of a decentralized architecture. It ensures better protection from cyberattacks and fraud. However, you will need to hire the right experts to handle the Blockchain development of your project.

2. Transparency

Decentralization of the data makes it tamperproof. Therefore, Blockchain will give you amazing transparency and trust. An unauthorized or single authority cannot alter the data present on the Blockchain. In fact, there must be a consensus among the participants of the Blockchain to make changes.

3. Tamper Proofing

As we mentioned above, tampering with the data present on a Blockchain is instantly visible. Therefore, tampering without anyone noticing will be impossible with Blockchain. Many businesses hire a Blockchain development company just to enjoy this feature.

4. Improved Efficiency

The ability to instantly verify and manage transactions on the Blockchain makes it incredible for improving the overall efficiency of a business.

Impact of Blockchain in the Manufacturing Industry

Apart from the above-mentioned benefits of Blockchain, it can have a significant impact on the manufacturing industry. For instance, Blockchain would be very helpful in connecting the ledgers from a supply chain to enhance the overall efficiency and accuracy while tracking a product.

-

Improvement in Tracking and Tracing of Assets

The manufacturing company might have a huge and complex supply chain. Moreover, a lot of distributors and stakeholders are involved in a supply chain. Using Blockchain technology can drastically streamline the operations and accuracy of various operations.

Above all, Blockchain technology gives end-to-end visibility and a single source of information to all the stakeholders of the supply chain. Building a mobile app for the manufacturing industry with Blockchain could resolve the common problem of lack of trust among the stakeholders. Therefore, efficiency and effectiveness could be guaranteed with Blockchain technology.

-

Better Protection of Intellectual Properties

When you are running a manufacturing business, you might have some trade secrets or intellectual properties. These secrets help you to innovate better and gain a competitive edge over others. The leak of such ideas and secrets could lead to legal issues and patient disputes.

The effective use of Blockchain technology could be a lifesaver for companies to provide the ownership of an I.P. Moreover, the use of NFTs can be super effective in determining the ownership of the information or I.P. It will provide a unique certificate in the form of an NFT to prove the ownership in a dispute. Effective Blockchain development is necessary to develop NFTs for your business.

Let’s discuss NFT to understand how it can be used for protected intellectual properties;

What is an NFT?

A Non-Fungible Token is basically a cryptographic or digital asset present on a Blockchain network. It can either be completely digital or can be used to back up real-world assets like real estate or artwork. Above all, NFT present on a Blockchain is encrypted and has a unique code.

However, NFTs are quite different from cryptocurrencies because they can’t be replicated or divided into multiple smaller units. Blockchain developers use complex encryption codes and digital signatures to protect NFTs against hacking, theft, hacking, etc.

Therefore, it makes complete sense to implement NFTs to secure intellectual properties from duplication, leaks, or other disputes.

Which Features of NFTs Will Help the Manufacturing Industry to Protect their I.P.?

Having a Blockchain development company by your side will help you ensure the effective implementation of NFTs in your manufacturing business. These are some of the best-known characteristics of NFTs that you will protect your I.P.;

a. Indivisible

It is not possible to divide an NFT into smaller denominations. Thus, an NFT is always meant to be a single and unique entity. In contrast, it is possible to divide cryptocurrencies into smaller units.

b. Authentic

Each NFT is meant to have a valid owner. Therefore, there couldn’t be any confusion about the ownership of an asset stored in an NFT. The ownership can only be transferred and verified instead of getting distributed.

c. Non-Interoperable

Each NFT present on a Blockchain will have a different value. Therefore, it is not possible to exchange them with other NFTs. Your I.P. will have better assurance of security with the non-interoperable nature of NFTs.

d. Tradable

It is possible to trade an NFT with the help of cryptocurrencies. However, the sale must be made on a valid NFT marketplace with smooth transactions. Thus, you can safely sell your I.P. to someone if necessary.

e. Programmability

Your team of Blockchain developers can have the complete freedom to customize an NFT with full creativity and innovation. Therefore, NFTs can be used for storing the most complex intellectual properties.

-

Improvement of Quality Checks with Simplification

Quality control is a major issue in the manufacturing industry. Ensuring quality helps an organization to provide better value to the customers and maintain its reputation in the market. Blockchain development can allow these organizations to provide complete transparency and documentation related to the quality control of the processes and the final product.

Customers can also be given a copy of these reports to get complete details about the quality control measures. With Blockchain, customers will have immutable documentation of practices behind the production process.

Above all, the database present in a Blockchain will help in identifying individual products, tags, each transaction, modification, or quality check on the final product. Having a mobile app for the manufacturing industry will help many organizations to have automated quality checks.

The effective use of Blockchain in manufacturing might remove the need for internal quality control to ensure the checks are performed by another supplier. Moreover, there could be a reduction in audits by central authorities and equipment manufacturers. Ultimately, automation in the quality control process would improve the overall efficiency of the manufacturing process. This is only possible when you have been working with effective Blockchain development.

-

Using Machines as a Service

It takes a huge investment to set up a manufacturing plant to produce something. There are a lot of machines and workforce that work together to create the final product.

Implementing Blockchain in manufacturing can help businesses to achieve a pay-per-use model for their machinery. Just like SaaS, they can rely on a new model known as machine as a service (MaaS).

Instead of purchasing the entire machine for production, the machinery owner can charge on the basis of usage. Therefore, the rent for the machine will be dependent upon the output it generates.

For example, instead of selling an entire unit of a blower, the owner will sell the blown air by volume. For this reason, the manufacturers will be able to save a lot in the production process instead of spending on large upfront investments. Accordingly, they can upgrade the equipment to gain access to the best technology available later. Effective Blockchain development will make the MaaS model a reality. The manufacturers will be able to scale their production incredible with flexibility and effectiveness.

-

Applying Automated Machine-Controlled Maintenance

Timely maintenance is a major issue in the manufacturing sector. Any delay or negligence in maintenance can lead to a halt in production or inefficiency. Blockchain in manufacturing could be very useful in supporting automated service agreements and shorter maintenance times.

This innovation would help organizations deal with the increasing complexity of heavy production machinery on a timely basis. Above all, they can rely on service agreements and installation documents to create a digital twin of a device in the Blockchain.

Blockchain development would allow complete automation in the execution and payment of scheduled maintenance. Any machine that needs maintenance can automatically raise a service request. Then, this request would be transformed into a smart contract to fix the device or find a replacement part. Upon fulfilment of the request, payment would be automatically released to the right party.

A prominent Blockchain development company can also help manufacturing companies implement immutable documentation of the complete maintenance history of the equipment. However, such automation of maintenance of machinery is still in the early development phase. Ultimately, it would drastically improve the health and reliability of the equipment and provide a better assessment of the machinery.

Real-World Use Cases of Blockchain in Manufacturing Industry

You can also implement similar use cases in your manufacturing business with the help of Blockchain developers. These are some of the popular use cases of Blockchain in manufacturing;

# Brilliant Earth: A Transparent Diamond Supply Chain

The diamond industry is infamous for sourcing diamonds from unethical resources and measures. In fact, a lot of child labor is also involved in diamond mining. And, it gets incredibly hard to trace the source and measures of mining along with the complete supply chain.

The consumers literally don’t have any transparency to ensure that the diamonds are harvested with ethical measures. Enter Brilliant Earth, a popular maker of diamonds and fine jewelry. They have successfully created a measure to track the supply of their diamonds with the help of Everledger Blockchain.

The effective use of Blockchain in manufacturing has enabled them to track the origins of their diamonds securely. Moreover, the customers also have a better assurance of their responsible practices while harvesting the diamonds.

Their Everledger Blockchain provides complete tracking with supporting documentation, including bills, certifications, and other important information. Ultimately, effective Blockchain development has made their supply chain more transparent, ethical, secure, and reliable.

Their customers have more detailed information about their Blockchain-enabled diamonds. In fact, they are able to browse the descriptions of individual diamonds, the chain of custody, critical insights, and other valuable information. Some of their offerings even have 360-degree videos to attract potential buyers. Ultimately, consumers are able to make better purchase decisions with the help of Blockchain in manufacturing.

# Walmart and Merck: Ensuring Drug Safety and Authenticity

The pharmaceutical industry has a huge responsibility to check the safety and authenticity of its manufactured drugs and medications. A single mistake could lead to the loss of hundreds of lives. Above all, ensuring consumer safety has been one of the most prominent use cases of Blockchain in manufacturing.

Walmart and Merck are already working on a Blockchain with the help of KPMG and IBM to enhance their drug safety and security program. The U.S. Food and Drug Administration’s Drug Supply Chain Security Act would be monitoring this pilot project program as well.

The FDA is also working with the help of Blockchain developers to define the testing methods and technologies behind an interoperable electronic system. Merck as a drug manufacturer, and Walmart, as a leading U.S. pharmacy, want to improve the efficiency of the supply chain.

Both IBM and KPMG are providing consulting services to these pharma companies with their expertise in information technology. The whole point behind this system is to ensure that their drugs are authentic from the source to the point when they are sold to consumers.

Implementing Blockchain in the manufacturing sector would create an augmentative layer in the supply chain. For this reason, drug manufacturers would be able to have unit-level visibility for better assurance of security. However, manufacturers need to spend hours in Blockchain development to ensure such robust architecture.

The involved companies have already completed the pilot program. In this program, Blockchain has proved the ideal technology to meet FDA’s special requirements for identifying, tracing, and tracking the drugs and prescribed medicines. Ultimately, this would improve drug safety and patient safety as well.

# FFF Enterprises: Ensuring Returns of Saleable Drugs

Along with verifying the safety of the supply chain of pharmaceutical drugs, Blockchain in manufacturing also helps in ensuring safer returns of drugs.

FFF Enterprises Inc., an innovative pharmaceutical distributor, has built a Blockchain network known as the MediLedger. Above all, this Blockchain network aims to have effective verification of sealable drugs. Moreover, it was also built for the pharmacy industry and is a part of the DSCSA pilot program.

The Blockchain powered ecosystem would be very useful for tracking and tracing US-prescribed drugs. Moreover, they have been testing and developing different digital products to execute on a Blockchain network that helps companies to comply with the DSCSA regulations.

In their Blockchain ecosystem, it is mandatory for all the returned medicines to have unique product identifiers. Accordingly, these product identifiers must be verified with the manufacturers so that distributors can resell them again. MediLedger has already been deployed commercially to verify the salable drug items. Above all, every returned drug can be verified at the unit level to ensure. Therefore, it would also help the authorities to learn about the items that are being put back into the stock and resold.

The MediLedger would be a great help to ensure that returned drug is actually coming from the person who bought it in the first place. Above all, this is only possible with the help of distributed ledger technology enabled by a private messaging network. This smooth communication layer between the involved parties would be very helpful in the product verification process.

# Bumble Bee Seafoods: Complete Tracking Info to Consumers

Today’s consumers often demand insights to learn about the origins of their food. Moreover, the meat and seafood industry is infamous for malpractices. Therefore, Blockchain in manufacturing can provide better visibility to the food supply chain.

Bumble Bee Seafoods, a prominent seafood company, is using SAP’s robust cloud platform to completely trace the journey of yellowfin tuna in the supply chain. Therefore, this Blockchain is responsible for tracking the entire journey of the fish from the oceans near Indonesia to local retailers in the U.S.

Blockchain’s incorruptible and verifiable characteristics help Bumble Bee Seafood safely share critical data between the parties. Above all, the Blockchain allows consumers to track the complete journey and history of their seafood products. They just have to scan the Q.A. codes placed on the tuna bags.

Effective Blockchain development is helping Bumble Bee Seafoods to show their efforts in sustainability and traceability efforts. Ultimately, users get the assurance that the seafood has been farmed ethically.

# Naturipe Farms: Delivering Fresh Fruits

Blockchain in manufacturing has the potential of true potential to provide insights into a company’s sustainability practices. For this reason, Naturipe Farms is using an SAP Blockchain platform for tracking the blueberries from the source of harvesting to the dinner table.

After plucking and packing the blueberries from the farm, Q.R. codes are carefully placed on the crates of the fruit. Thus, consumers can scan Q.R. codes of individual packages to learn about the origins of those berries. Plus, they can also obtain information on the sustainability practices on the farms.

Handwritten notes usually do the current process of tracking fruits. This traditional process can cause delays in delivering the blueberries to the consumers. However, this is not an ideal solution since Blueberries have a very short shelf life. Effective Blockchain development ensures easy capturing of data and a smoother supply line.

# Tony’s Chocolonely: Forced Labor-Free Chocolate

Cocoa beans are mainly found in African countries such as Ghana and the Ivory Coast, which produce almost 60% of the global cocoa production. However, the supply chain of this industry isn’t very clean. In fact, it often includes malpractices such as child-labor or slave-labor.

An Amsterdam-based company, Tony’s Chocolonely, has been working on a pilot program with the help of Accenture to develop a private Blockchain. This network is getting tested with the supply chain partners present in the Ivory Coast region.

Socoopacdi and Ocean have been testing the Blockchain system to enter data related to cocoa bean collection, local traders, and international traders. Through this system, Blockchain can be effectively used to track the batches of the beans through the supply chain.

Tony’s Chocolonely now has a fully operational method of tracking the journey of its cocoa beans in the supply chain. Ultimately, this is only possible with the help of effective Blockchain development.

Many more companies in the chocolate industry realize the importance of Blockchain in tracking the supply chain. For this reason, hiring a prominent Blockchain development company would be a sensible decision. This would help you to innovate your supply chain in manufacturing industry.

What is the Future of Blockchain in Manufacturing Industry?

The blockchain in manufacturing industry is responsible for empowering hundreds of other industries. In fact, it is getting massively transformed with innovative technologies like A.I., Machine Learning, IoT, and Blockchain. With the growing maturity of Blockchain technology, manufacturers will be able to overcome the common challenges faced while manufacturing products.

Effective Blockchain development from skilled Blockchain developers will help businesses to ensure more efficient operations, openness in data sharing, and collaboration. Machinery will be more connected to the internet to achieve better efficiency and effectiveness.

Traditional supply chains will be transformed with more cost-effective solutions that focus on reducing paperwork and increasing speed. Having Blockchain technology would drastically improve the standards, improve trust, and speed of the production process. Moreover, it would be less dependent on human validation at every step of the manufacturing process.

Hiring MobileCoderz for Blockchain Development

Blockchain is a very complex technology with a lot of tools and frameworks. Thus, it won’t be advisable for you to develop a Blockchain-based app on your own. Hiring a prominent Blockchain development company like MobileCodez would be the ideal choice to get the best implementation of Blockchain technology in your business. Above all, we have extensive experience with the technology and have helped multiple clients from diverse industry verticals to implement innovative Blockchain solutions.

-

Mobilecoderz Awarded as India’s Best iPhone App Development Company by Clutch

Mobilecoderz Awarded as India’s Best iPhone App Development Company by Clutch -

How Much Does It Cost to Develop a SaaS Application?

How Much Does It Cost to Develop a SaaS Application? -

Mobilecoderz recognized as the Top App Development Company in Saudi Arabia by GoodFirms

Mobilecoderz recognized as the Top App Development Company in Saudi Arabia by GoodFirms